Within this sector we have been focusing on the aesthetic components and bodywork produced utilizing various production technologies.

Lapis S.r.l. works closely with major Tier 1 automobile manufacturers, in order to identify production inherent problems and optimize components before starting the construction of equipment.

Examples of projects where Lapis S.r.l. implemented the co–design phase, and was responsible for the production of equipment and carried out the sampling are:

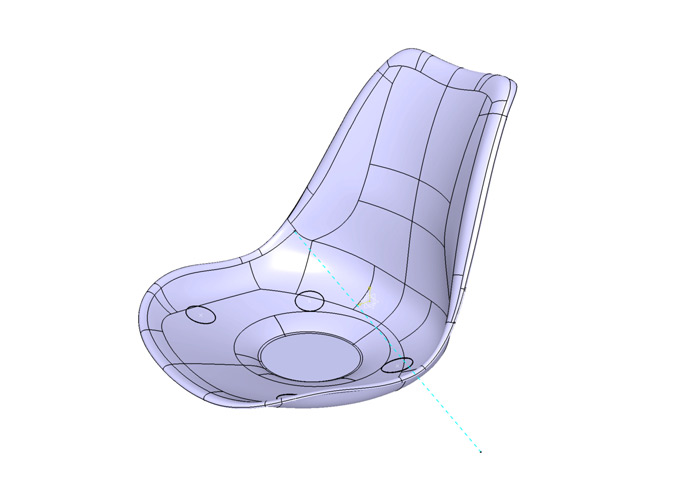

Lapis S.r.l. has grown over the years gaining a great deal of experience in developing

complete bodywork for the motorcycle and scooter industries.

The company can provide the complete development of all bodywork, from the optical scanning of the style mockup, to the building of “class A” surfaces working closely with the customer’s design center.

The detailed design of the individual components is always made keeping in mind the production technology required, in order to hand over a project ready for the next stage of mold’s manufacturing.

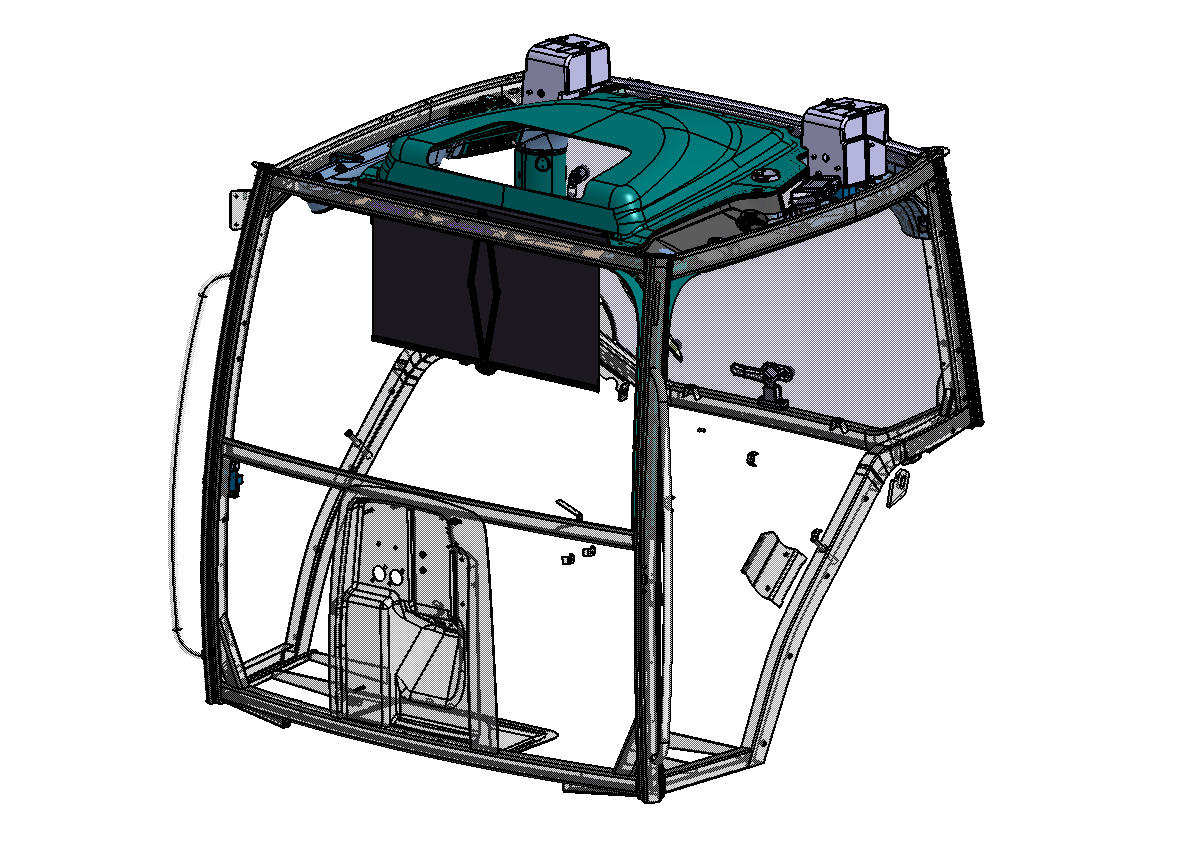

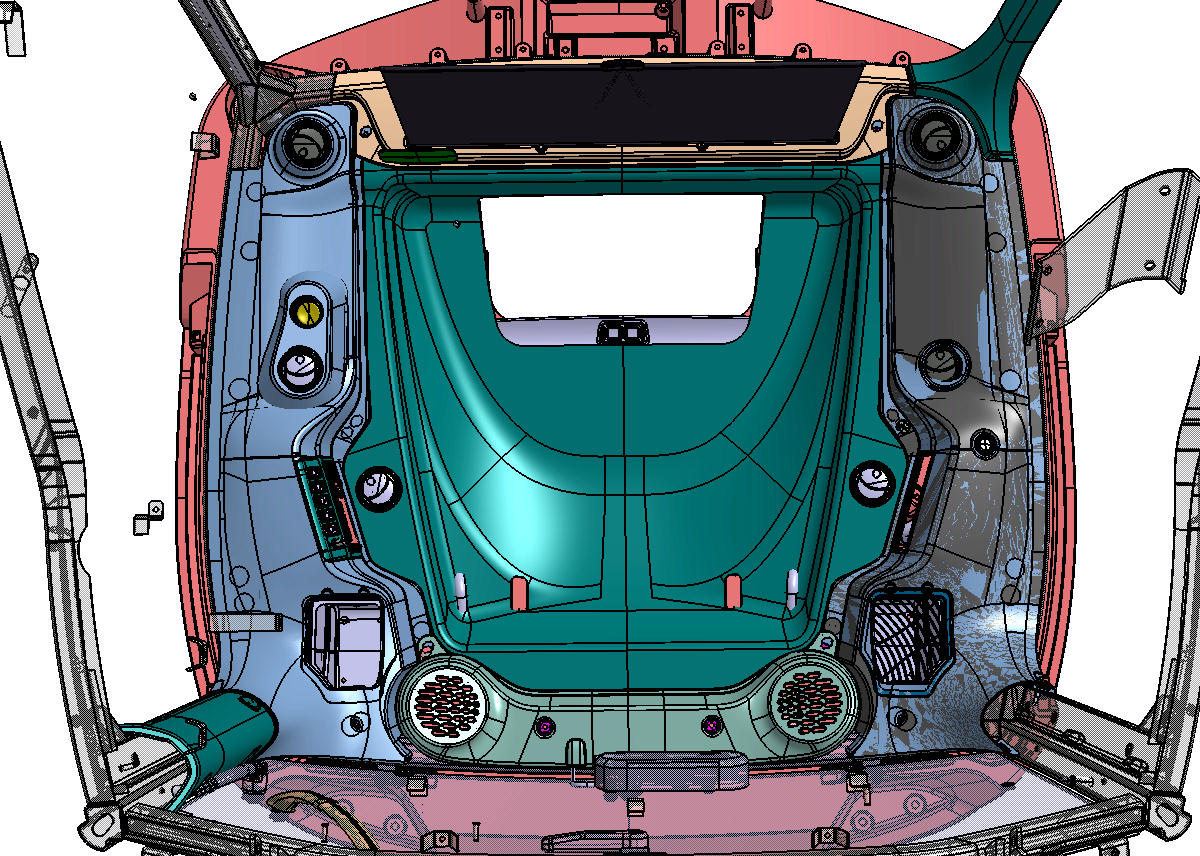

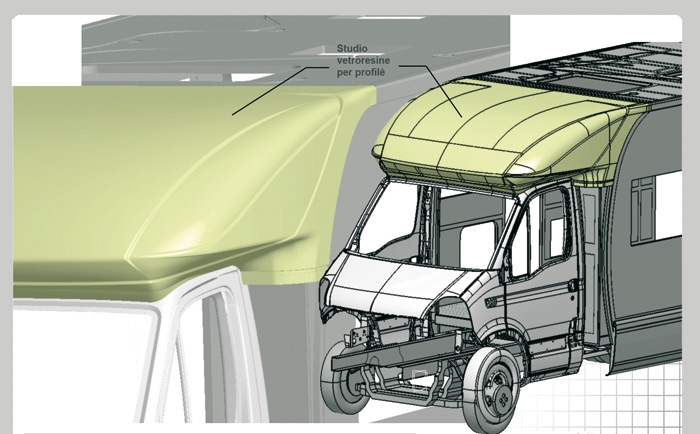

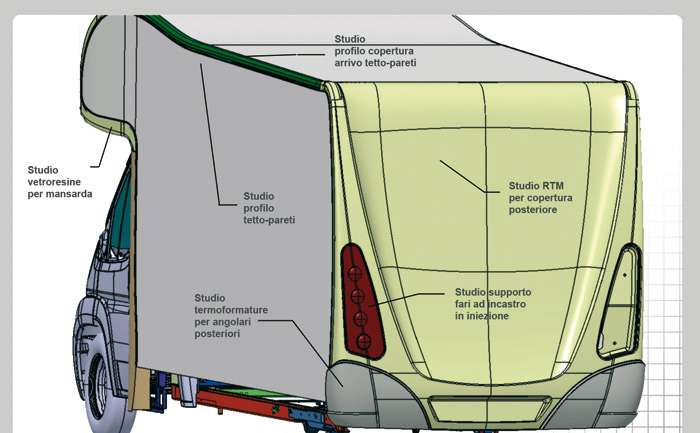

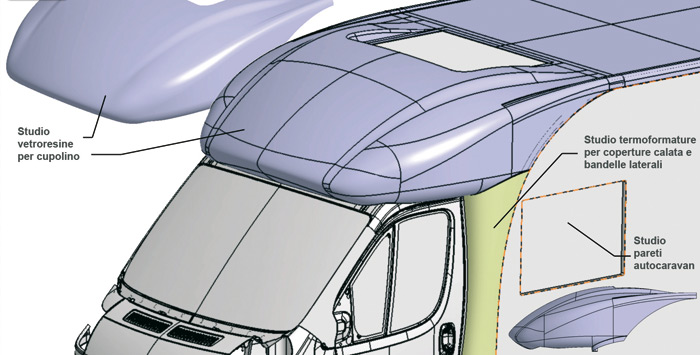

Lapis S.r.l. provides design services and construction equipment services also in niche areas such as

heavy transport and

agricultural vehicles.

In this field, it is very important for the company to have wide experience in using production technologies suitable for medium/low volume parts and to be able to meet specific technical requirements.

From the development of all the interiors for the operator’s cabin, to the development of external bodywork components made of composite materials (SMC), Lapis S.r.l. can support the customer with the most suitable solutions and production technologies.

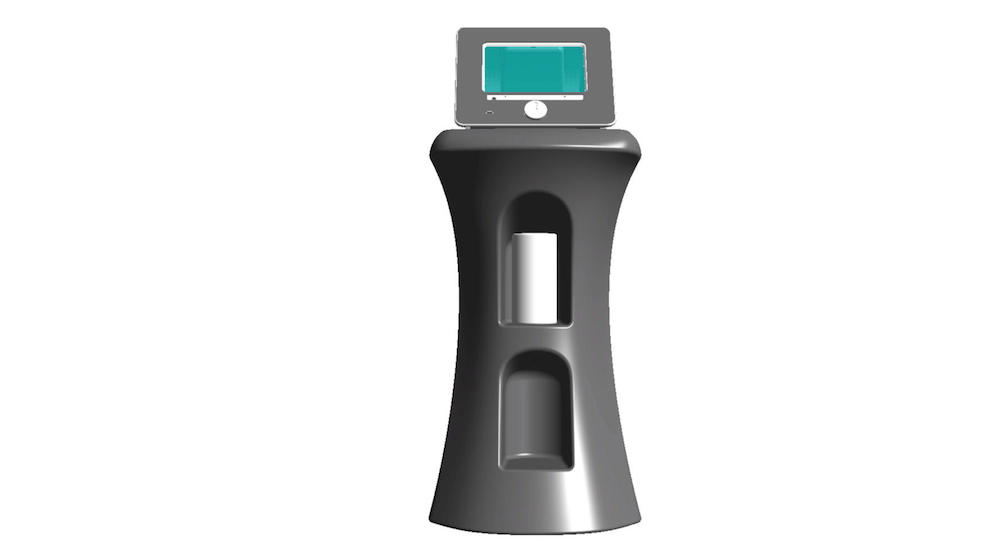

The

eclecticism of the company allows it to operate in different industries where the skills in

design and manufacture of plastic, composite or metal components are required.

Some examples are:

If the customer needs a product

aesthetically appealing and eye-catching, Lapis S.r.l. can provide support in the study of a new design and in the crafting of coating and custom covers.

Following are some examples.