The company is equipped with ATOS (Advanced Topometric Optical Sensor) digitizing system, capable of performing, even at the customers’ site, a precise three-dimensional relief of any kind and size of object.

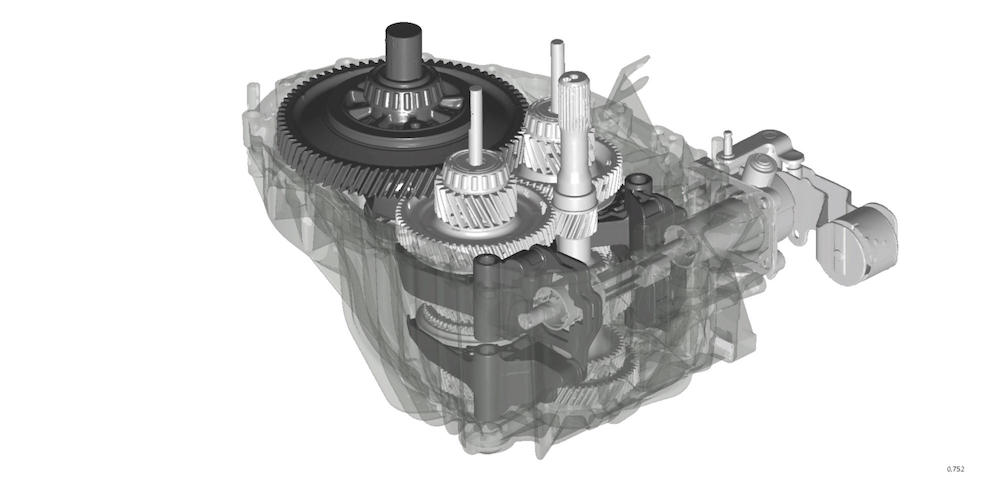

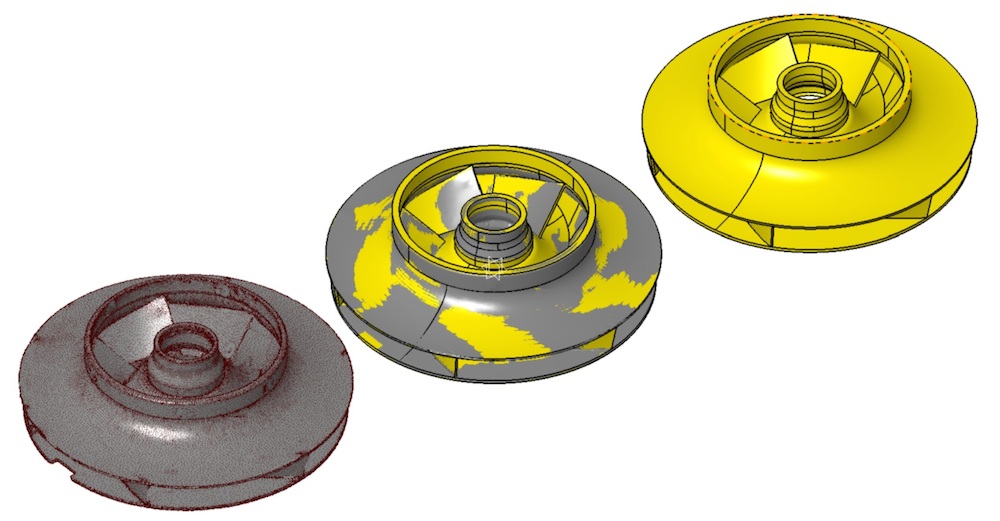

Through this technology, Lapis S.r.l. is able to perform processes such as: reverse engineering, dimensional control, duplication of molds and models.

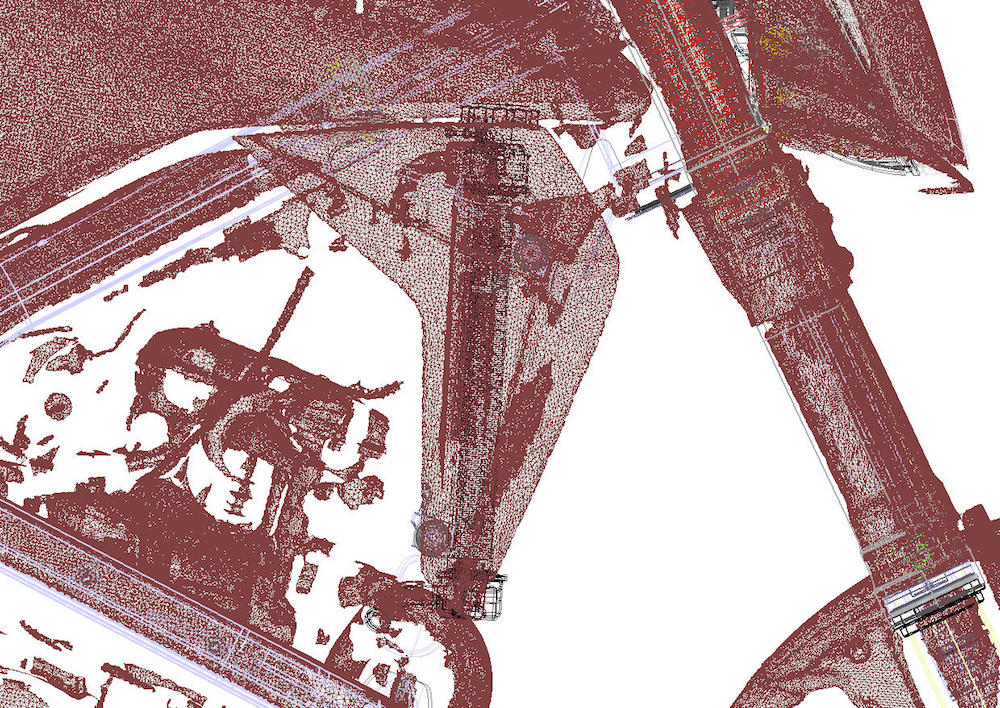

ATOS is an innovative and highly productive optical/topometrical digitizing system. Using two combined techniques and exploiting high resolution lenses we can make the 3D-scan in a tenth of the time required in traditional systems needing contact, with the advantage of providing a very high density cloud of points. Thanks to a powerful management software, the system is totally autonomous and can be easily and quickly deployed anywhere.

It is composed of a PC, an image processing/storing device and a sensor mounted on a tripod. The sensor consists of a projector at the center that projects fringe lights and two cameras (CCD) at the sides. The cameras “see” the fringes projected and measure the surface trend, calculating the depth.

The management software, which processes the images, generate a “cloud” of points that can be imported into CAD systems. In the presence of shadow and hidden areas, or depending on the size of the physical model, the acquisition process can be split into several phases. The clouds of points resulting from the various ” photographs ” may be joined together without deformation; thus, they can be generated perfectly consistent with the reference system. Dedicated ” markers”, placed on the model to be digitized, are used to originate a real ” frame ” on which the clouds of points are placed. Thanks to this ingenious and effective system, there are no limits to the size of the object whose shapes are to be digitalized.